As a business owner, the most important thing about a cardboard shipping box is that it safely gets your products to your customers. You want your box quality to withstand the shipping and transportation process. When shipping with FedEx and UPS, how can you ensure your boxes won’t get crushed when they arrive at their destinations?

Estimated reading time: 5 minutes

We’ll walk you through what makes up the best shipping box quality, your boxes’ minimum crush test for FedEx and UPS, and when you should use double-wall vs. single-wall boxes.

What Makes Up Box Quality?

Before we jump into minimums for FedEx and UPS, let’s talk about box quality and why it matters.

Each shipping carrier has maximums and minimums for both package weight and package dimension. For most e-commerce businesses, your product will likely fall within the acceptable ranges. But shipping carriers like FedEx and UPS don’t have set minimums or maximums when it comes to box quality. Each carrier requires that your shipping box be sturdy and undamaged. They also rely on the customer to properly and securely pack their own boxes before shipping. This leaves your box choices wide open. Let’s look at how to find the appropriate box quality for your product.

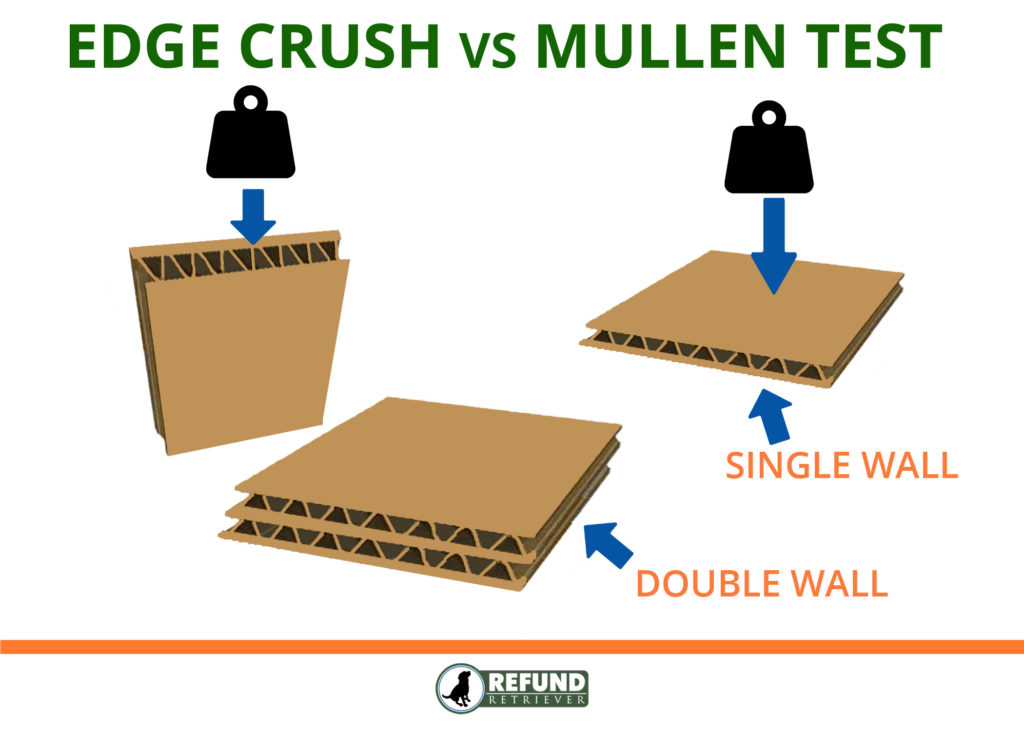

The packaging industry has two primary ways of measuring the strength and durability of a cardboard shipping box. The industry uses two tests designed to determine the same thing but in different ways. The tests tell you how much pressure your package can take before it breaks.

The Edge Crush Test (ECT)

The Edge Crush Test also referred to as ECT, was designed to test and measure the durability of a corrugated cardboard box. It works by applying pressure to either the top or bottom of the box and seeing how much it can withstand when vertical before collapsing.

The ECT tests the strength of a shipping box from top to bottom. This is important when boxes are stacked on each other when shipped in pallets. Invented in the 1990s, the ECT is the most common test used. As a result, 32 ECT is the most common corrugated box sold.

Boxes with a 32 ECT can hold up to 40 pounds. Both FedEx and UPS accept 32 ECT boxes. If your product weighs more than 40 pounds, shipping carriers recommend higher ECT boxes.

The Mullen Test

The Mullen Test, or Bursting Test, tests the bursting strength of a corrugated cardboard box. It determines how much pressure the walls of a shipping box can handle before it bursts. With this test, corrugated boxes must have a minimum base weight requirement, meaning they’ll be heavier boxes by default than boxes measured by the ECT.

While the standard result of the ECT is 32, the standard result of the Mullen test is 200# — measured in pounds. The higher the number, the stronger the box. While the ECT focuses on how a box will hold up while stacked, the Mullen test focuses on how a box will hold up when handled individually, including when it’s handled roughly and how much weight it can hold.

Both FedEx and UPS accept 200# boxes. If your product weighs over 40 pounds, shipping carriers recommend using higher Mullen Test-rated boxes.

Double-Wall vs. Single-Wall Boxes

Now that we’ve established the two major tests the packaging industry uses to measure cardboard shipping box strength, let’s dive into when you should use double-wall or single-wall boxes.

What’s the difference between the two types? Double-wall boxes have two layers of corrugated fluting. These boxes are most commonly used for heavy-duty shipping. The thicker the box’s walls, the sturdier the box. But don’t be fooled by the name. Even though they are used for heavy-duty products, double-wall boxes must still measure up to the ECT or Mullen test.

Single-wall boxes have just one layer of corrugated fluting. These boxes are still sturdy but have a limit to the weight they can hold. Single-wall boxes are the most commonly used for e-commerce business owners.

Boxes to Avoid

Boxes not measured with the ECT or Mullen Test

When shopping for boxes online, you’ll see the product specifications in the details of each product description. Most corrugated boxes have a 32 ECT or 200# specification. This measurement is like having the packaging industry’s stamp of approval. Without that spec on the page, you risk ending up with boxes that aren’t sturdy or durable.

Boxes that hold less than 40 pounds

A standard corrugated box should have 32 ECT or 200#, which can hold up to 40 pounds of product. Most boxes that have the 32 ECT stamp can hold a range of weights from 30 pounds up to 65 pounds. However, if you use a container that can hold no more than 30 pounds, you may have crushed shipping boxes and angry customers to deal with later.

Used boxes

Don’t sacrifice box quality just to save a few dollars. Used boxes may have more dents and bruises than a new one. It’s best to avoid the stress of wondering whether or not the product you worked so hard on will reach its destination in one piece.

Best Shipping Box Quality Conclusion

When shopping for shipping boxes, remember to look for the packaging industry’s stamp of approval. 32 ECT and 200# boxes are the most common boxes accepted. They’ll hold up to 40 pounds of weight. Brandable Box shipping boxes are made from 100% recycled materials and have a 32 ECT. It’s the best of both worlds.